I wait with great interest the outcome of your experiment.

It would be great if such a barrel-band could use the lightening-cut and hand-guard spring inlet on a sportered original stock. Also, if a quick detachable swivel stud could screw directly into the barrel-band nut.

Barrel Band for Krag Sporter

-

Onlinebutlersrangers

- Posts: 9875

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Barrel Band for Krag Sporter

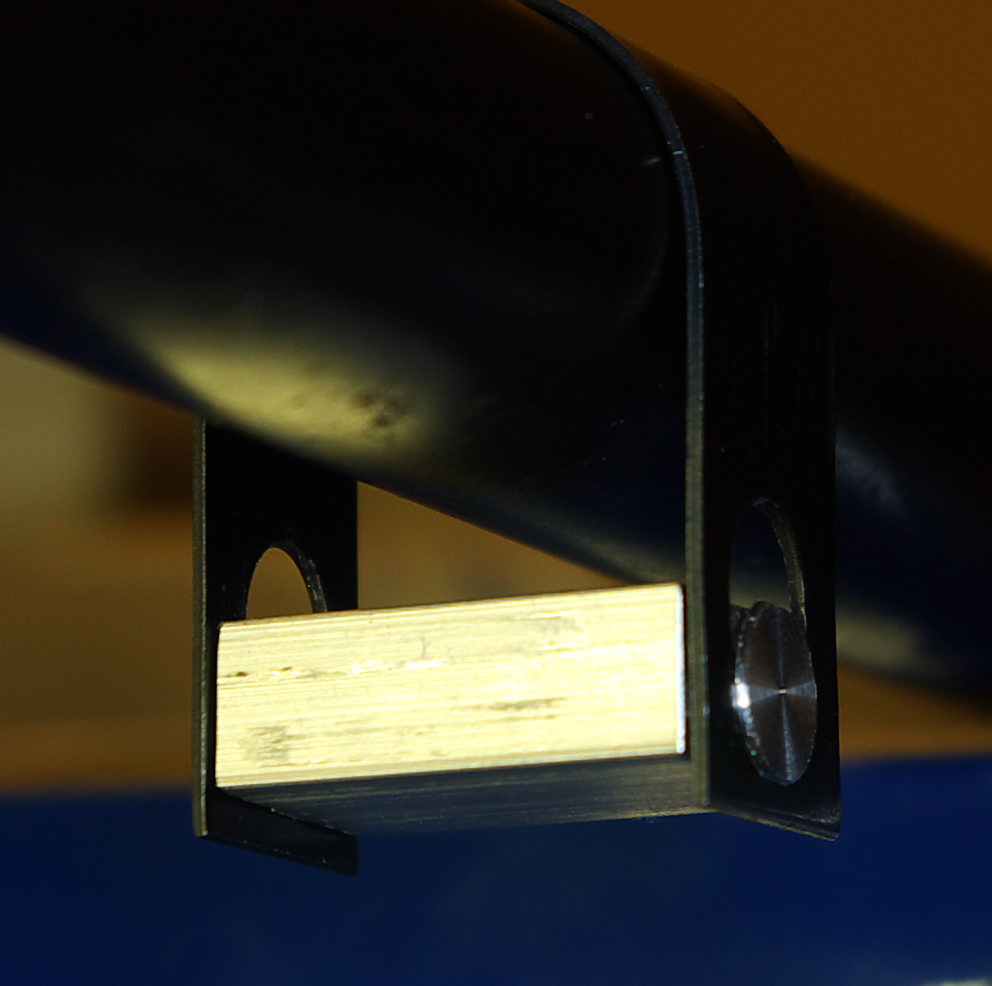

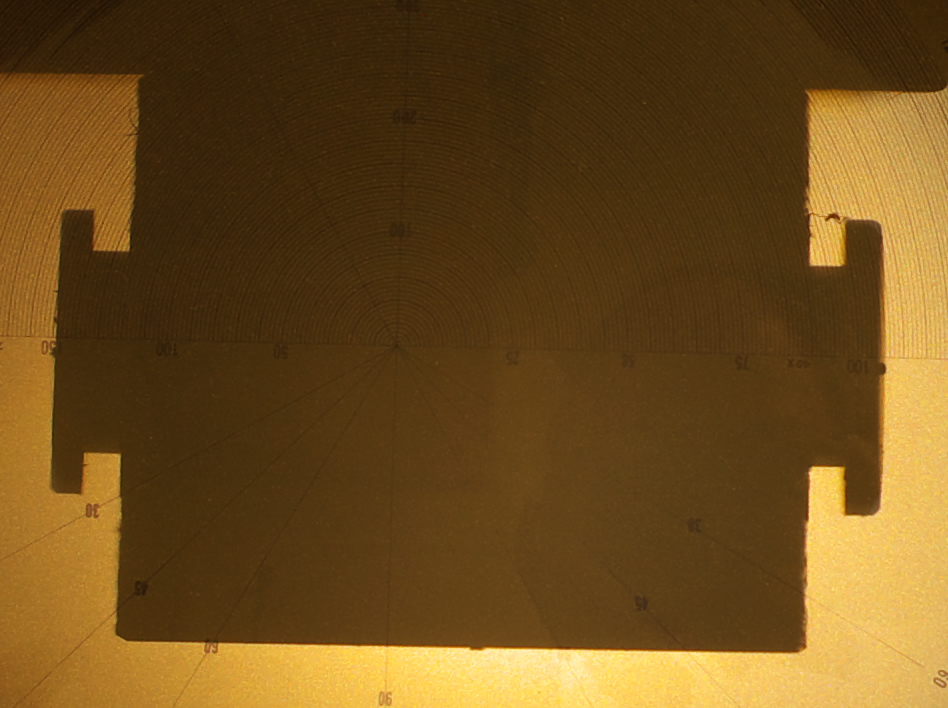

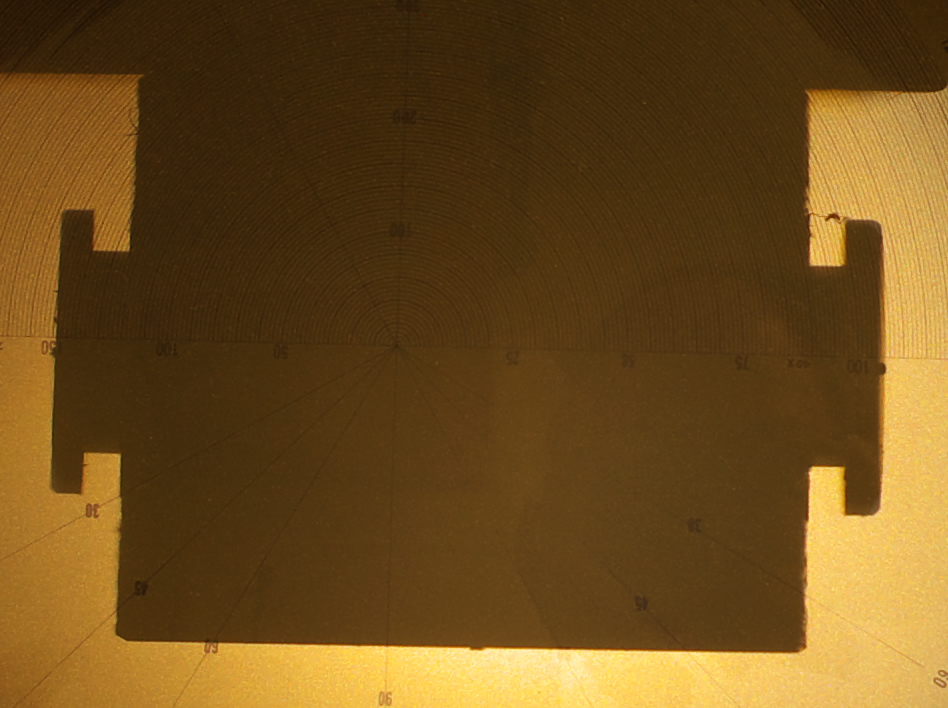

Well here it is less the 1/4-28 tapped hole. To get this in the stock it will need a pocket 15/16 wide, 9/16 length wise (parallel to the barrel) and 1/2 deep from the bottom of the barrel channel. I think a 1/8 thick washer inletted into the stock would do. Between this washer and the bottom of the 1/2 deep hole I think 3/16 of wood would suffice.

So from the bottom of the barrel channel to the bottom of the stock 13/16 minimum. the photo is showing the band at 12.5 inches from the receiver, at 10 inches there is some obvious distortion in the band but I am sure tension would pull it flush with the barrel all round.

With B/R's suggestion that the screw also hold the sling swivel a little more thought would have to go into this.

Stock work would need to involve drilling a 1/4 inch hole through the center of the barrel channel. I would use some sort of piloted drill to make a 1/2 pocket from the top and maybe a 7/8 pocket from the bottom. The pocket in the barrel channel would get the rectangle shape 1/2 deep with a Dremel tool. Make a countersunk 7/8 washer for the bottom and screw it in.

So from the bottom of the barrel channel to the bottom of the stock 13/16 minimum. the photo is showing the band at 12.5 inches from the receiver, at 10 inches there is some obvious distortion in the band but I am sure tension would pull it flush with the barrel all round.

With B/R's suggestion that the screw also hold the sling swivel a little more thought would have to go into this.

Stock work would need to involve drilling a 1/4 inch hole through the center of the barrel channel. I would use some sort of piloted drill to make a 1/2 pocket from the top and maybe a 7/8 pocket from the bottom. The pocket in the barrel channel would get the rectangle shape 1/2 deep with a Dremel tool. Make a countersunk 7/8 washer for the bottom and screw it in.

- Parashooter

- Posts: 707

- Joined: Thu Feb 04, 2010 5:14 am

- Location: Kragmudgeon House, CT

Re: Barrel Band for Krag Sporter

Why make the block so wide? The Savage drawing shows the band recurved at the lower extremities and a block appearing equilateral. Is the band not readily amenable to a bit of bending to allow a smaller block?

Re: Barrel Band for Krag Sporter

You are right I thought the width would have been 1/2 inch also from the illustration. The band material is .025 thick and about as springy as feeler gauge stock. I was afraid to bend it more thinking I would get a permanent deformation. The 2 ends are bent out on purpose and the getting the width down to 1/2 may work correctly with those bends. I still have all the tools in the lathe so I can do a couple more. I will try one at .6 and .5 inches. If the .6 works without feeling like I am permanently deforming the band then I will try the .5 inch.

Also need to rethink what bottom of the stock will need, a 7/8 inch washer there would look terrible even if it was coned to sort of match the contour of the stock.

Brownels has a couple of "barrel bands " in their catalog. Maybe they have an online photo. I can tell nothing from their print illustration.

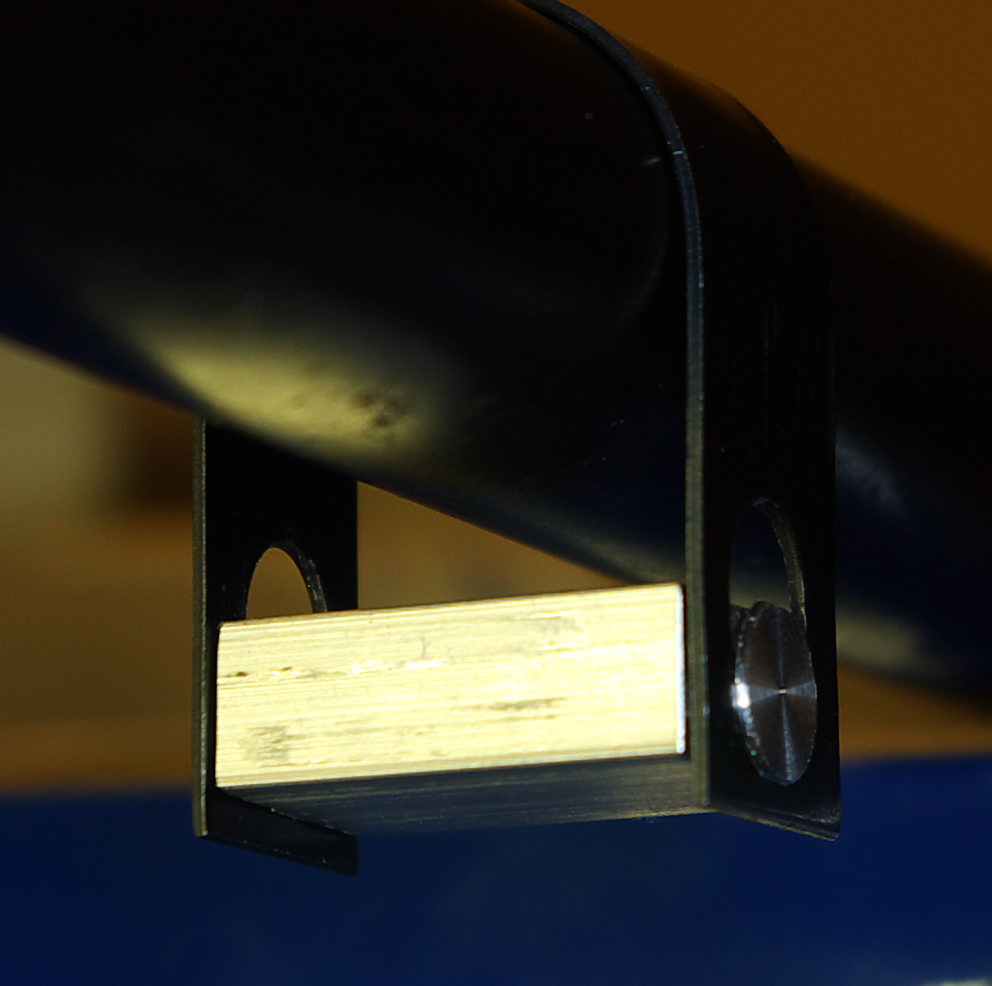

The attached photo shows the top of the band, nothing moved since the first photo. Matches the barrel radius pretty well at 12.5 inches.

Also need to rethink what bottom of the stock will need, a 7/8 inch washer there would look terrible even if it was coned to sort of match the contour of the stock.

Brownels has a couple of "barrel bands " in their catalog. Maybe they have an online photo. I can tell nothing from their print illustration.

The attached photo shows the top of the band, nothing moved since the first photo. Matches the barrel radius pretty well at 12.5 inches.

-

Onlinebutlersrangers

- Posts: 9875

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Barrel Band for Krag Sporter

FWIW - My two cents - I would make the nut in a trapazoid shape. The longer parallel side would be at the top. I would groove that side to fit close to the barrel.

The angled sides would be as long as necessary or desired. A cross hole through the angled sides would accomodate a cross-pin, notched at the ends, to link with the band.

The short parallel side, at the bottom of this rig, would be drilled and tapped for desired screw or de-tachable swivel stud.

I do not see merit in keeping the barrel-band 'sides' parallel. If they are drawn inward, less wood will need to be removed.

The angled sides would be as long as necessary or desired. A cross hole through the angled sides would accomodate a cross-pin, notched at the ends, to link with the band.

The short parallel side, at the bottom of this rig, would be drilled and tapped for desired screw or de-tachable swivel stud.

I do not see merit in keeping the barrel-band 'sides' parallel. If they are drawn inward, less wood will need to be removed.

- Parashooter

- Posts: 707

- Joined: Thu Feb 04, 2010 5:14 am

- Location: Kragmudgeon House, CT

Re: Barrel Band for Krag Sporter

FWIW - My two cents - I would make the nut in a trapazoid shape. . .

I think that idea is worth at least fifty cents. Solves a whole bunch of fabrication and fitting problems!

Re: Barrel Band for Krag Sporter

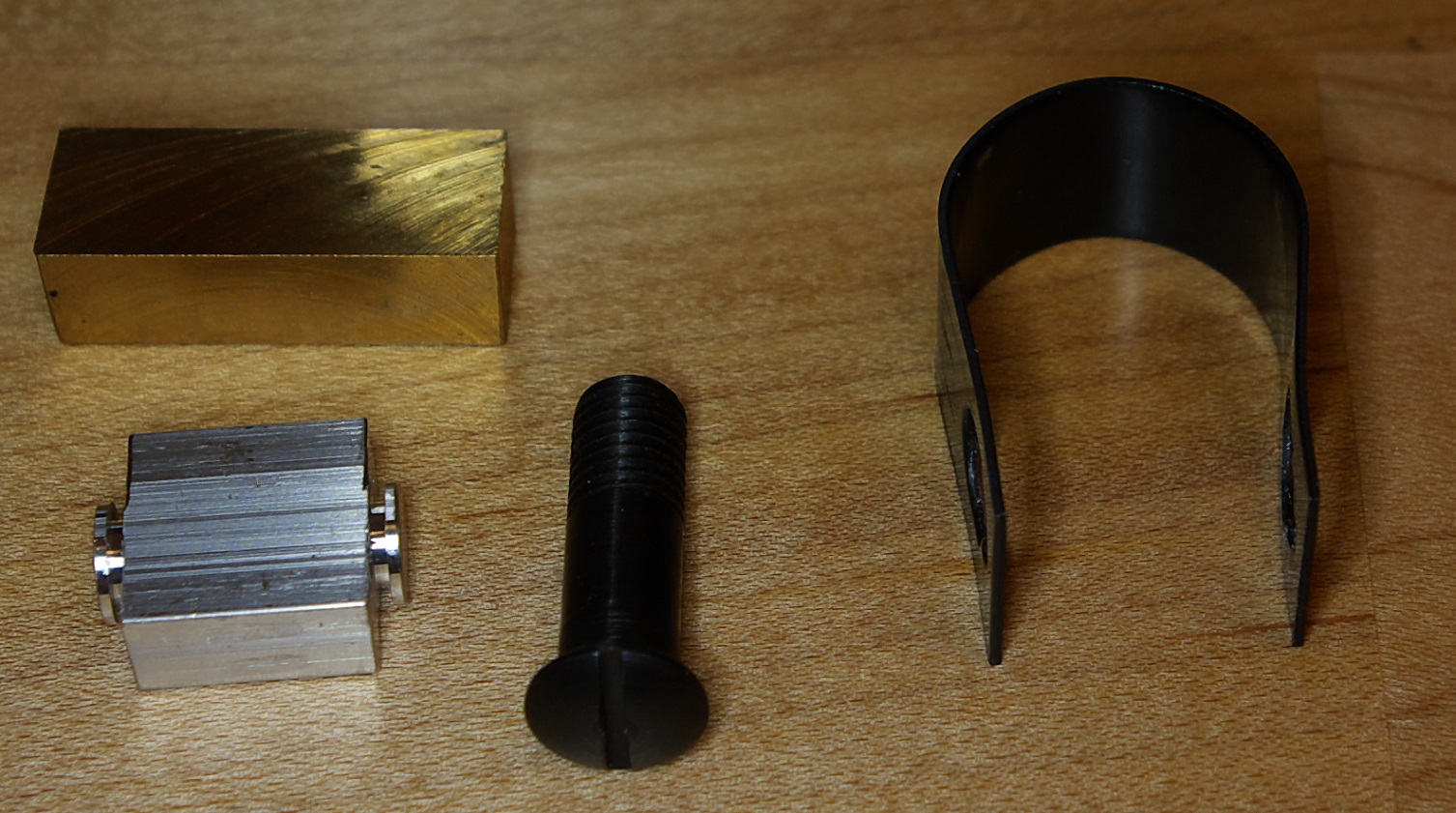

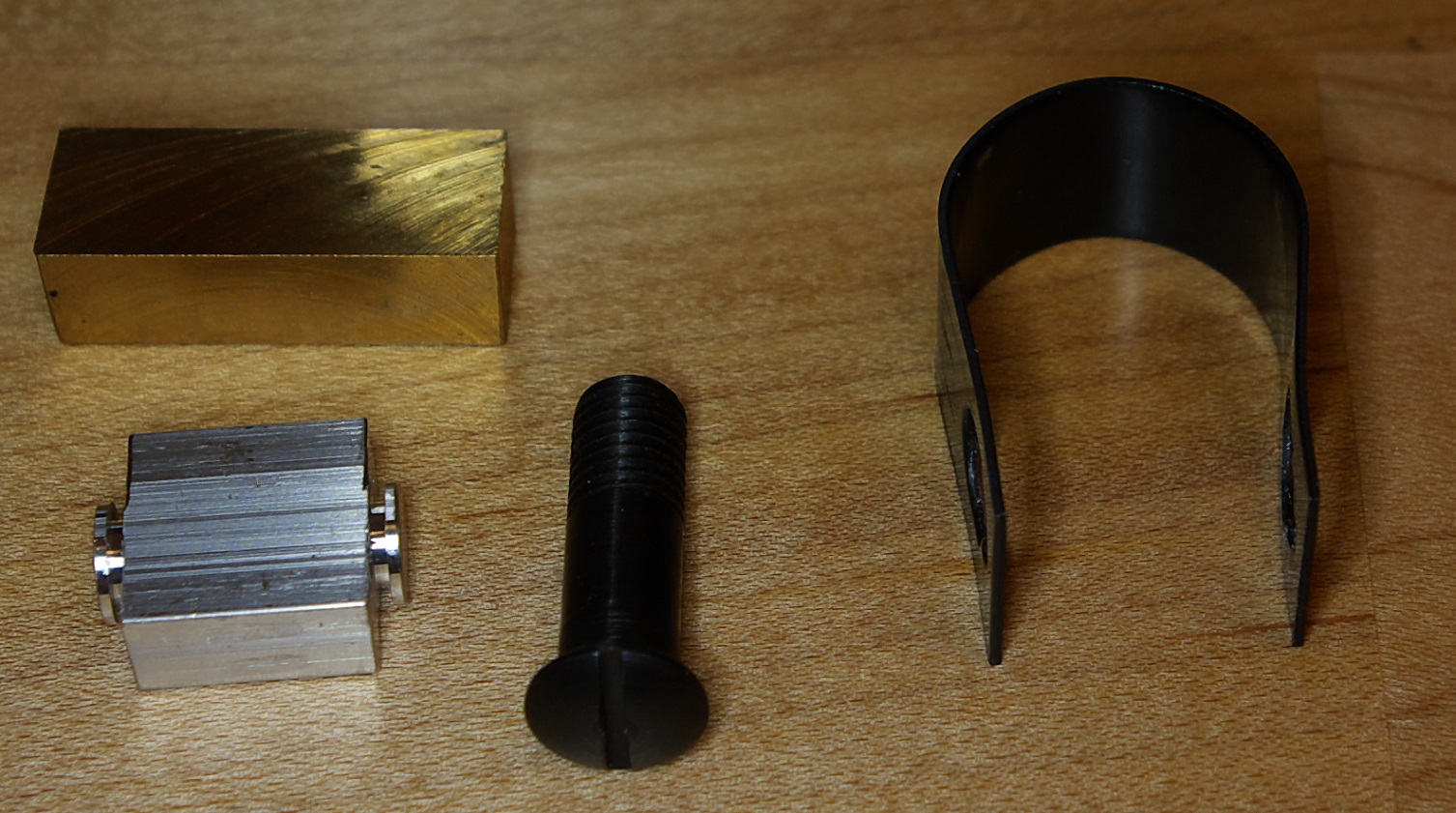

Even though the trapezoid has some desirable is not doable without some expensive tooling or shop built fixtures. I did a .6 and .5 inch copies. The .6 is just a bit wider than the barrel at 12.5 inches, the .5 is definitely narrower than the barrel. I did get both on the barrel the .6 started to get tight about 13.5 inches out and could be pushed to 12.5 easy enough. It did not scratch the bluing as the edges of the strap are rounded somewhat. The .5 had to be started on the barrel with some force. the barrel is cut off at 18 inches. Without prebending the strap it will be difficult to get it mounted behind the sight on Jim's barrel. I will try to get it so that it can be wrapped around the barrel and get the nut properly engaged behind the sight with either of the 2 smaller nuts.

We will let Jim see how much room he has on the fore end and bend to fit that nut. We want to see how wide the fore end is at 12.5 inches from the front of the receiver and how deep from the bottom of the barrel channel to the bottom of the stock at that point.

We will let Jim see how much room he has on the fore end and bend to fit that nut. We want to see how wide the fore end is at 12.5 inches from the front of the receiver and how deep from the bottom of the barrel channel to the bottom of the stock at that point.

-

RomeoJim

Re: Barrel Band for Krag Sporter

Awesome work FredC. We're at our cabin right now but I'm anxious to get home to measure the barrel and stock width and depth from 12.5" out from the receiver. Direct attachment of the sling swivel to the barrel band mount screw ideally would provide the most strength, but appears to cause difficulty with design to accommodate that.

If the swivel stud can be installed relatively close to the the barrel band, wouldn't the rigidity obtained by the stock's attachment to the barrel band provide adequate strength to prevent stock fracture?

THANKS to you for your interest, expertise, and work on this issue

If the swivel stud can be installed relatively close to the the barrel band, wouldn't the rigidity obtained by the stock's attachment to the barrel band provide adequate strength to prevent stock fracture?

THANKS to you for your interest, expertise, and work on this issue

Re: Barrel Band for Krag Sporter

Quote "Direct attachment of the sling swivel to the barrel band mount screw ideally would provide the most strength, but appears to cause difficulty with design to accommodate that."

Not necessarily, it could be the easiest attachment, if the

swivel is heal be a single screw. I have not tapped these nuts yet. if you find a swivel that uses a 1/4 inch or 10-32 screw in the center and is meant to be full tightness I can tap the nut with the appropriate thread.

Quote "If the swivel stud can be installed relatively close to the barrel band, wouldn't the rigidity obtained by the stock's attachment to the barrel band provide adequate strength to prevent stock fracture?" This could work as well.

What to do with the hole in the bottom of the stock? A pain 7/8 countersunk washer would not look right. I like Dick's term escutcheon, so lets call it that instead of washer. If you like the color of the aluminum bonze in the photo, I could round the ends and drill the appropriate hole in the center to be a relative snug fit to keep it from wallow then letting your swivel get loose. I have a small pile of these aluminum bronze ends from a production job we did 20 years ago. It does not seem to tarnish or discolor with age. How would you or a gunsmith make the inset in the stock for a escutcheon? I would do it on a milling machine, but it has been done other ways for centuries now.

The band took a set from forcing it on to the barrel I was able to pull the nut out of the band easily and have no doubt it will install as easily. It does have enough tension when installed that it will hold the nut fairly tight when lowered into the stock and be located so you can start the screw.

Not necessarily, it could be the easiest attachment, if the

swivel is heal be a single screw. I have not tapped these nuts yet. if you find a swivel that uses a 1/4 inch or 10-32 screw in the center and is meant to be full tightness I can tap the nut with the appropriate thread.

Quote "If the swivel stud can be installed relatively close to the barrel band, wouldn't the rigidity obtained by the stock's attachment to the barrel band provide adequate strength to prevent stock fracture?" This could work as well.

What to do with the hole in the bottom of the stock? A pain 7/8 countersunk washer would not look right. I like Dick's term escutcheon, so lets call it that instead of washer. If you like the color of the aluminum bonze in the photo, I could round the ends and drill the appropriate hole in the center to be a relative snug fit to keep it from wallow then letting your swivel get loose. I have a small pile of these aluminum bronze ends from a production job we did 20 years ago. It does not seem to tarnish or discolor with age. How would you or a gunsmith make the inset in the stock for a escutcheon? I would do it on a milling machine, but it has been done other ways for centuries now.

The band took a set from forcing it on to the barrel I was able to pull the nut out of the band easily and have no doubt it will install as easily. It does have enough tension when installed that it will hold the nut fairly tight when lowered into the stock and be located so you can start the screw.

- Dick Hosmer

- Posts: 2284

- Joined: Sun Nov 20, 2005 4:11 pm

Re: Barrel Band for Krag Sporter

With sincere apologies to the fine craftsman and machinists involved, I think this thing is going off the rails with complexity. When done, everything will be concealed except the top of the band, the slots cut in the wood and the bottom screw with its' escutcheon. What goes on "in the hole" could (should) be as simplistic (even fugly) as possible, especially for those who just want a barrel holder. Adding the swivel to the mix might introduce additonal issues, depending on what style is used. Just my .02 - wish I could work on this at the bench, but my "shop" (such as it is, i'm only a tinkerer) is not available at present, nor will it be for several months.