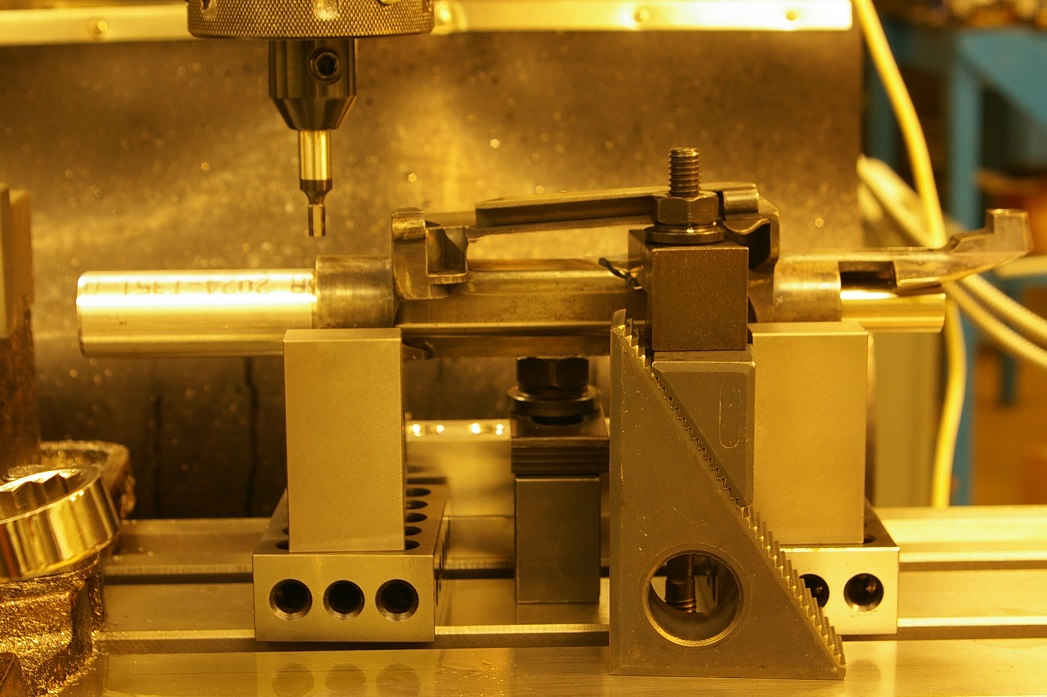

This is the last planned installment of this thread. The first photo shows the fixture still level after milling the front guard screw area. This got the cut out centered to the action and wide enough for the new guard as well as finishing the new pillar to the correct height.

After that but not pictured, I indicated the stock level near the front sight pillar and milled the pillar flat and cleaned up the epoxy that got in this area (A brass cover is planned for this recess).

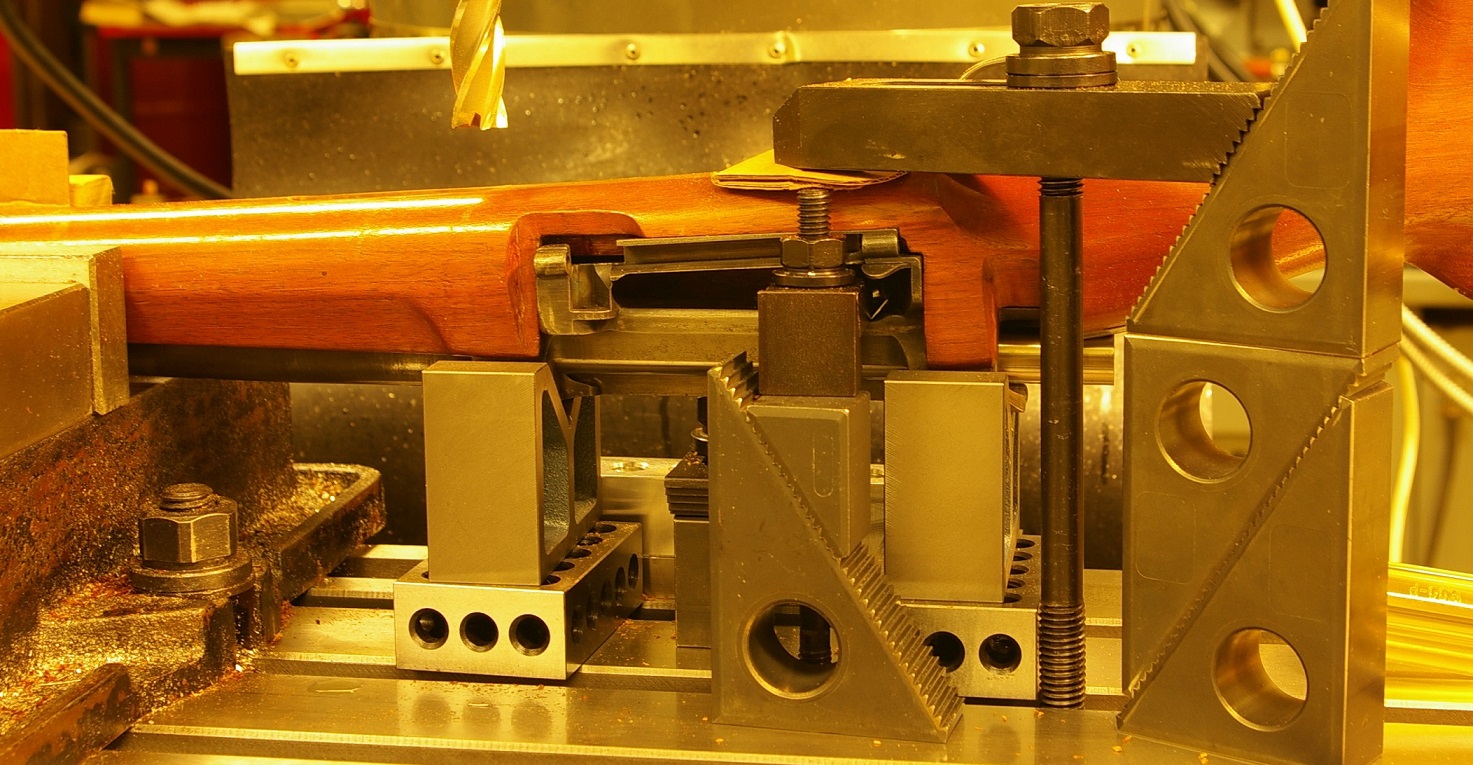

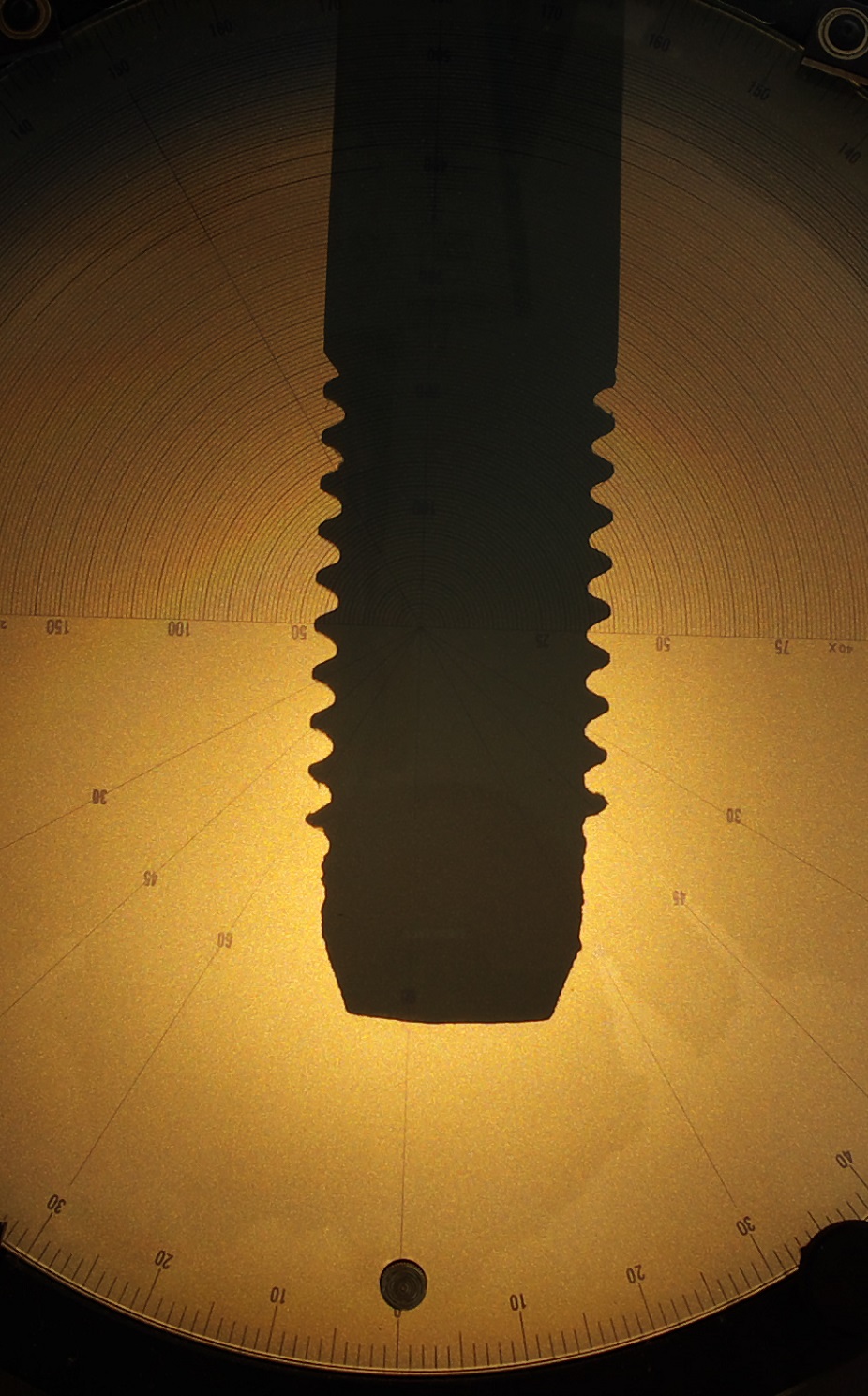

The last photo shows indicating a gauge pin in to find the center line of that screw and finish dialing in the 5 degree angle. That cut was made till the guard was appropriately deep and the pillar cleaned up.

In other threads it has been mentioned that some after market stocks are very hard to get fitted. This last fixture could go a long way in making the trigger guard match the receiver. I would not recommend going the trigger guard pillar route unless you are cleaning up someone else's mess.

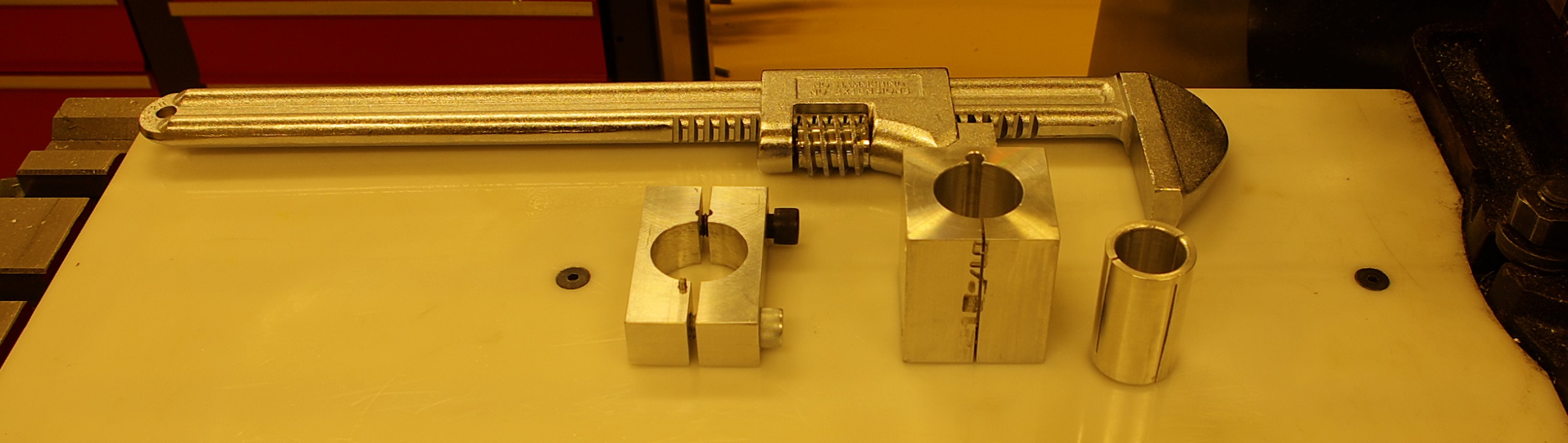

Making the pillars involves cutting the 4 1/2 degree angle on the front one, the 5 degree angle on the back one. I engraved a line on each after milling the angles then transfered a matching scribed line to opposite side to line them up. The transferred lines have to be lined up as the pillars are tightened down. The distance between the screw heads has to be set before the assembly can be epoxied into the stock. A lot of thought went into the process and I still got it wrong and had to mill the rear trigger guard hole a little off center to make things fit.

Hopefully this information will be helpful to members that have access to a lathe and mill. If you do not, maybe your favorite gunsmith can use it to become a better Krag smith.

I will be glad to answer any questions if I can remember the answers. (insert smiley here)

I do have 2 of the angles and may never need to use one again, if you are your favorite Kragsmith needs one let me know.