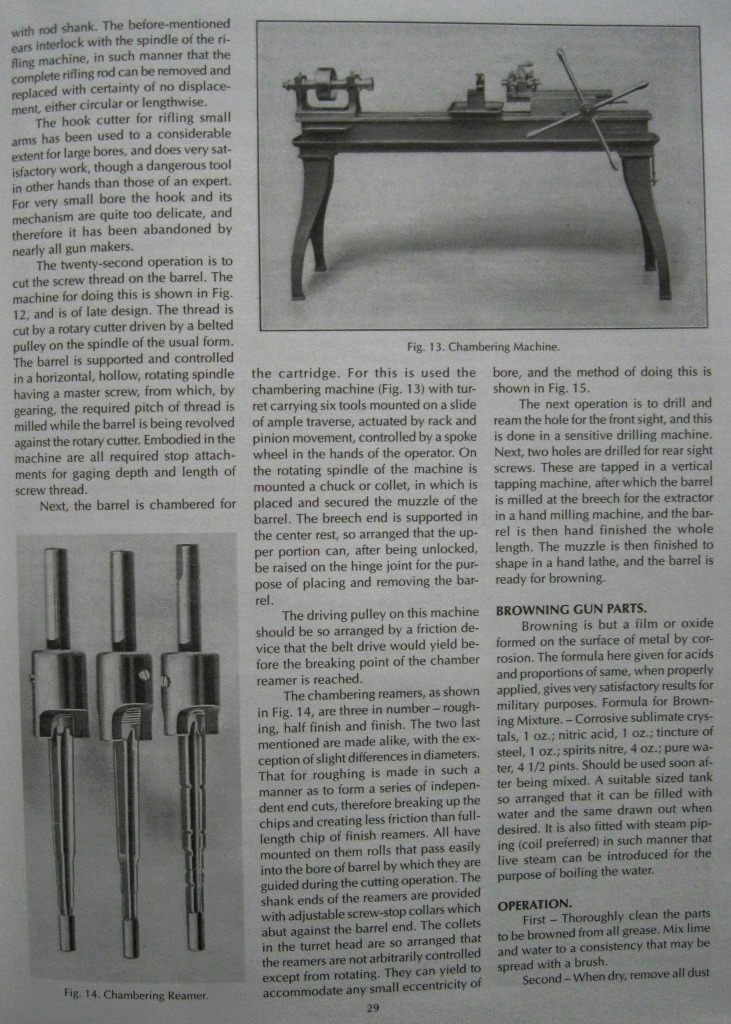

. . . Just found a reference to drilling and reaming the front sight hole. Must be another 30 caliber barrel being described, not Krag. . .

I suspect the hole in question is for the blade retaining pin - drilled straight then reamed to the taper that has frustrated so many who attempt removal in the wrong direction. :-X

If so then the mill cut and soldering the front base would have already been installed in a separate timed or clocked operation. Possible, I guess. Too, bad all the ones that worked there are dead and can not solve the puzzle.

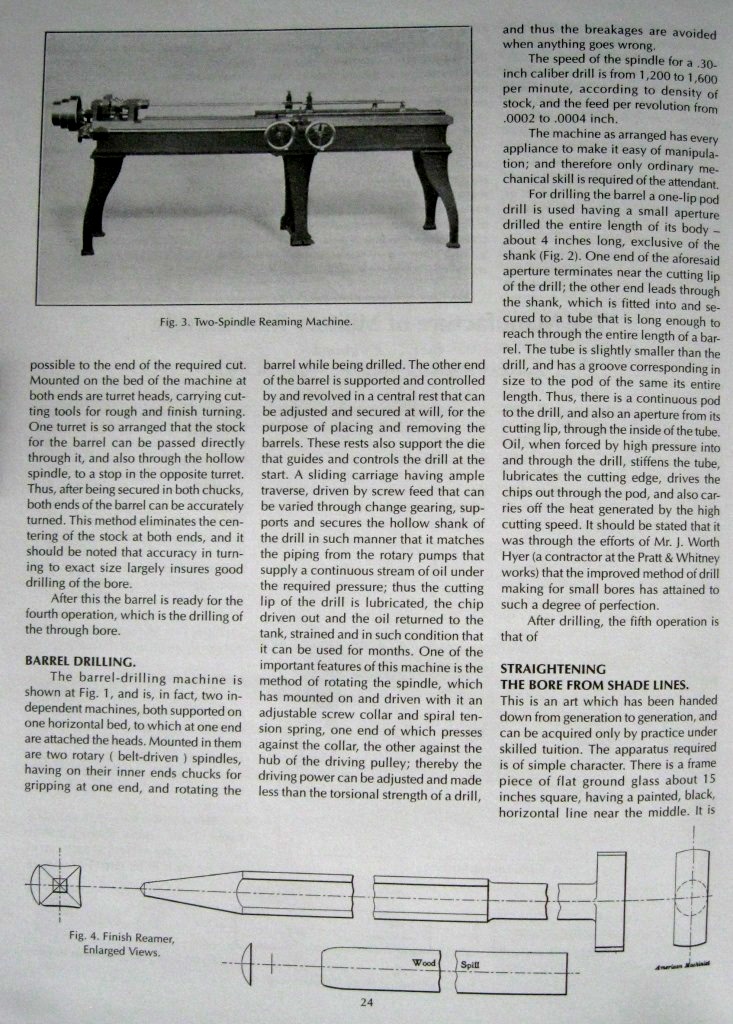

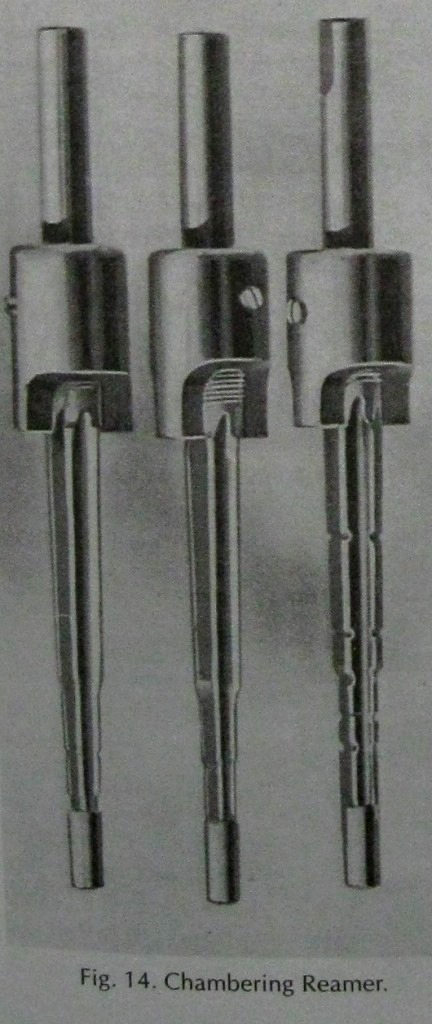

The article did mention drilling with a sensitive drill then reaming. If the reaming was with a tapered reamer that would fit and this could be Krag barrels described. ?????

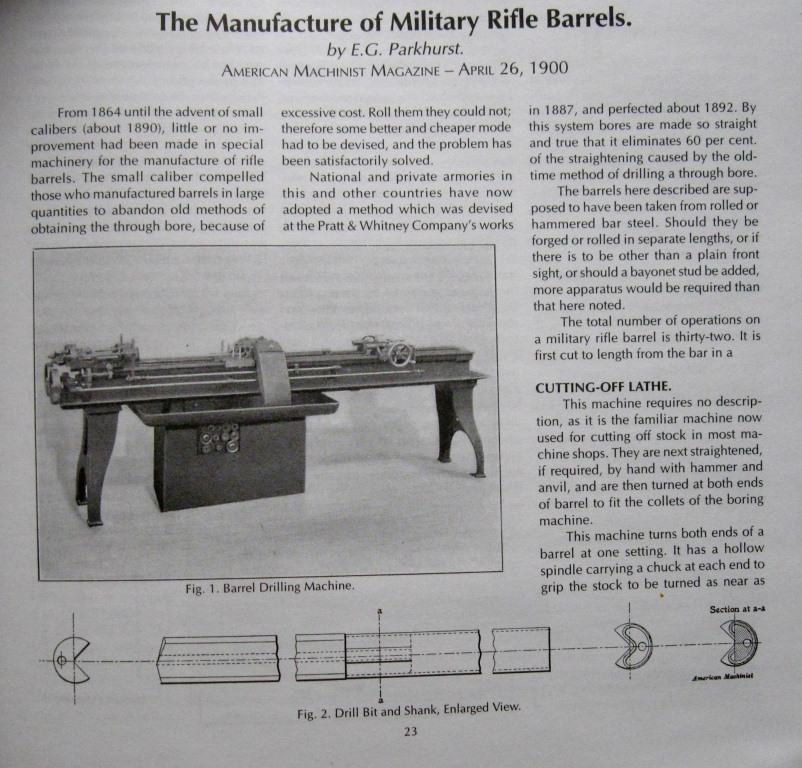

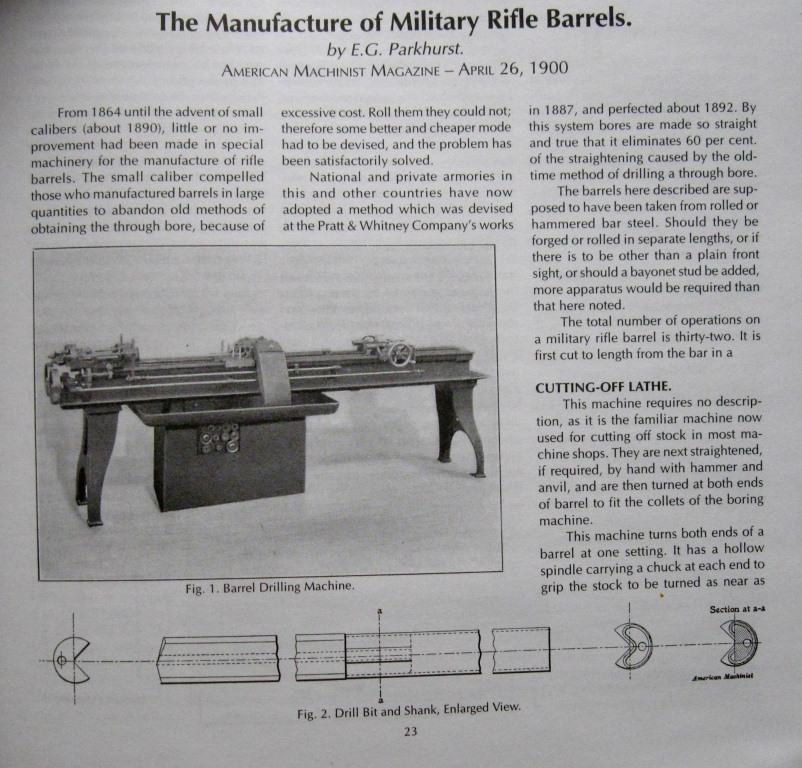

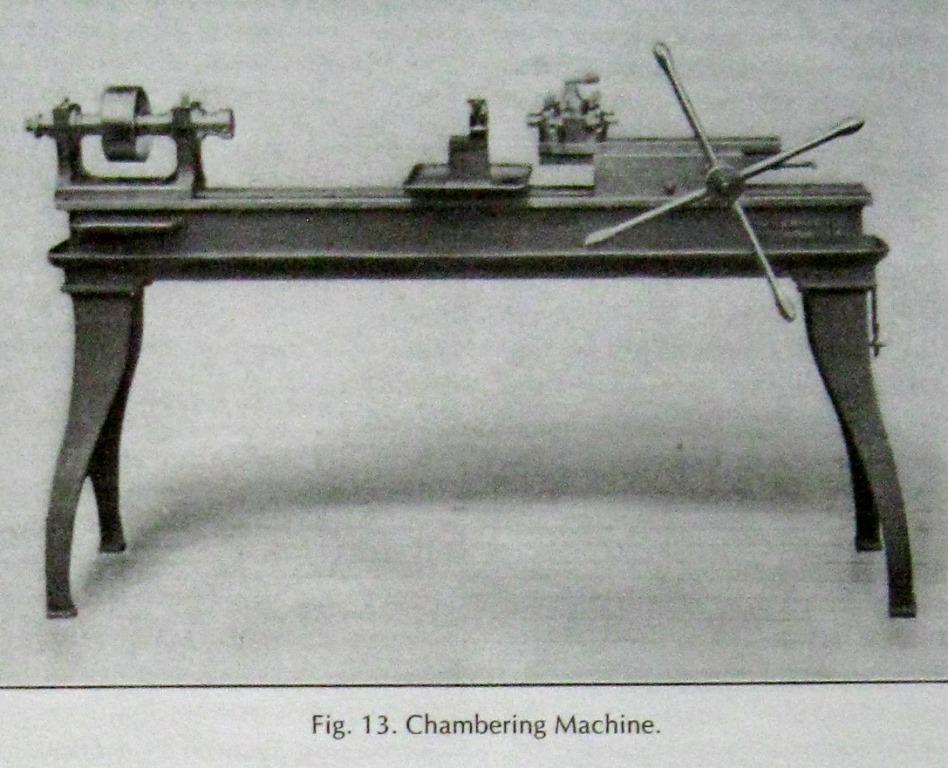

Went back and looked for a drawing of the drilling machine, not included, if it had been it might have had revealing clues.

Parashooter,

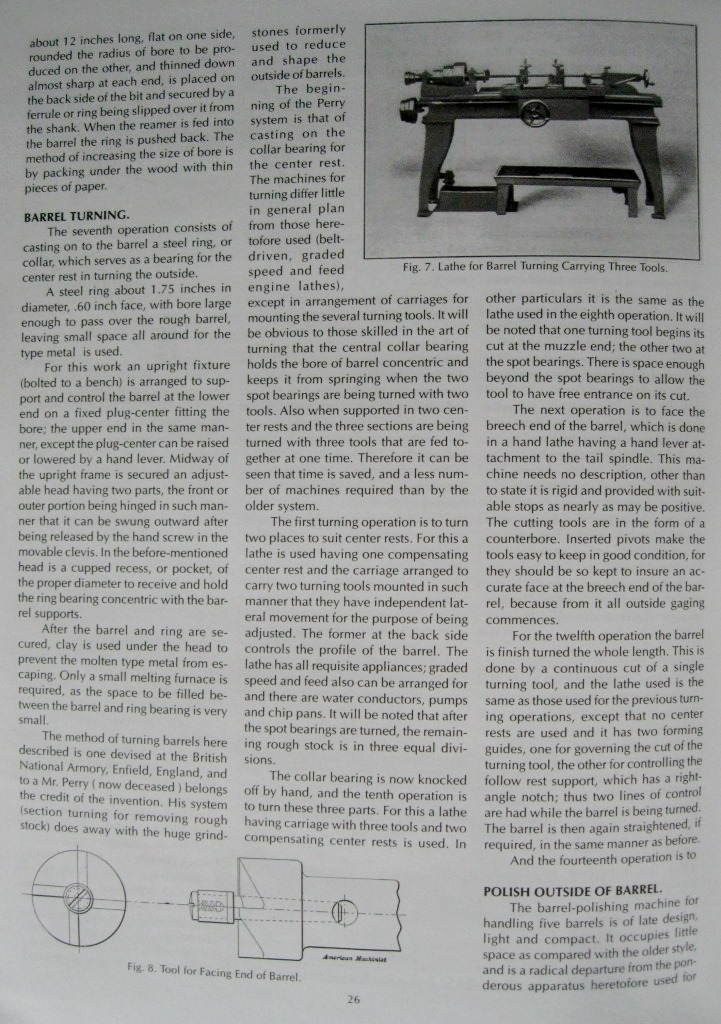

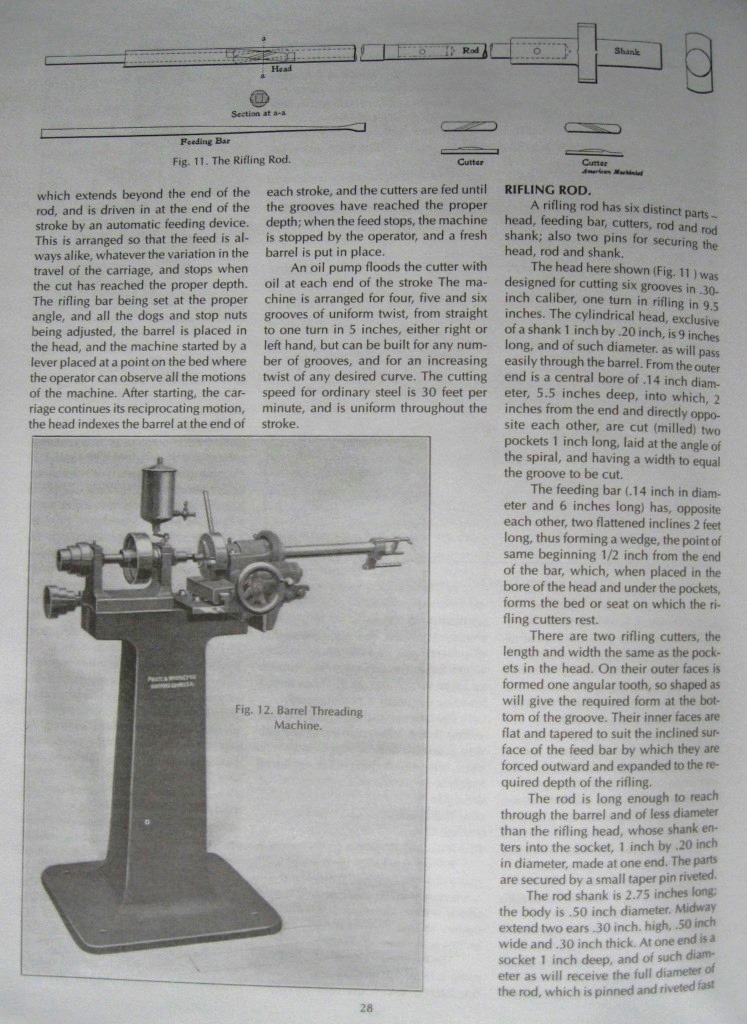

Went back and looked at the reamers and they sure look like 30/40. 1900 is probably too early to be tooling up for the 03-A3 Springfield.