Any chance the rifle has some kind of improved chamber, with correct rim thickness and a deepened chamber?

On firing the shoulder blows out a bunch and you have to move it way back to fit the sporter?

Not sure if there were any Ackley improved reamers for 30/40. Maybe some kind of wild cat?

Chamber differences and tough to close bolt

- butlersrangers

- Posts: 9898

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Chamber differences and tough to close bolt

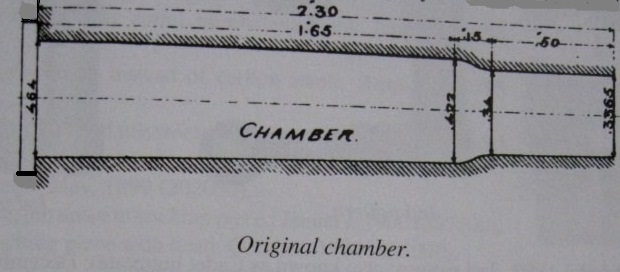

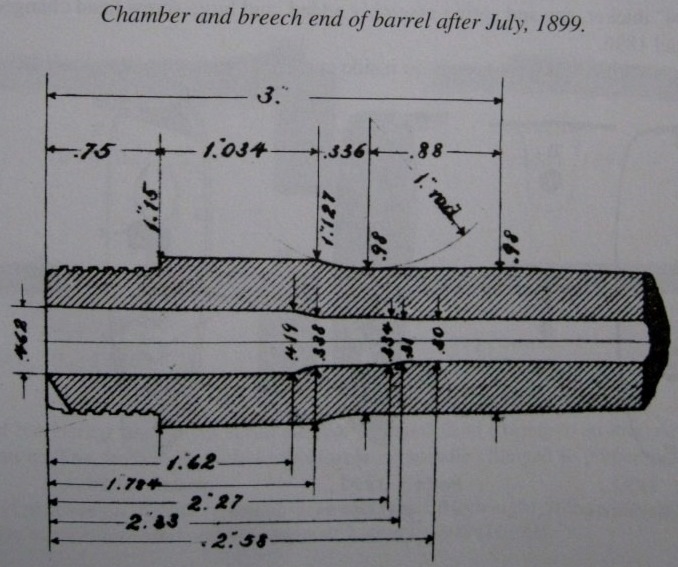

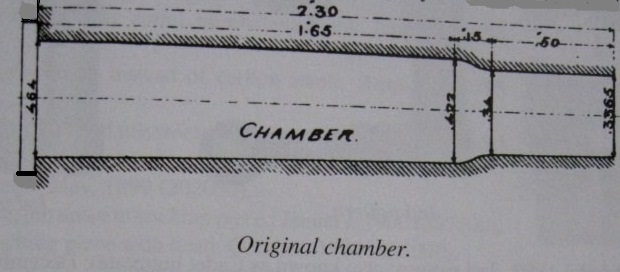

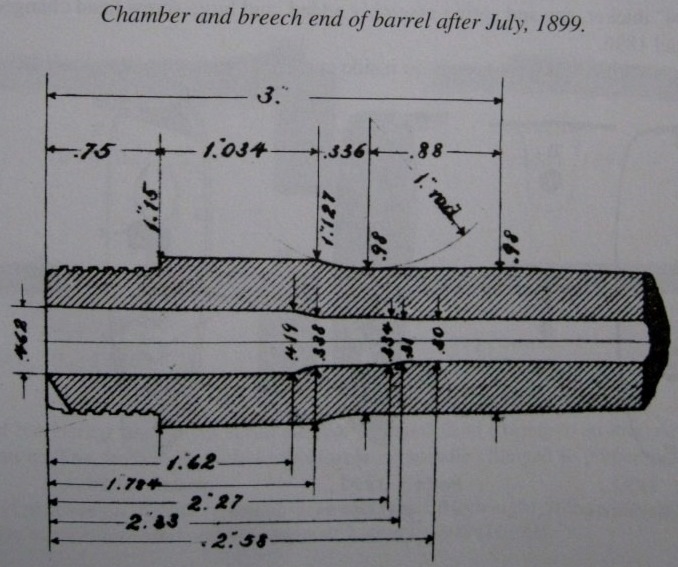

Note - Per Mallory - The change in chamber dimensions occurred at around serial number 213,000.

If Mallory was correct, Model 1898 Krags (below that number), and model 1896 & model 1892 Krags, may have more liberally dimension-ed chambers.

FWIW - (Re-barreled Krags can totally different. I use to have a model 1898 'cut-down', that was put together by Sedgley. The replacement barrel was made from a (1905 dated) 1903 Springfield barrel. The tight chamber would accept factory ammo and my F.L. resized cases. It would not accept a 'fired case' from any of my other Krags).

If Mallory was correct, Model 1898 Krags (below that number), and model 1896 & model 1892 Krags, may have more liberally dimension-ed chambers.

FWIW - (Re-barreled Krags can totally different. I use to have a model 1898 'cut-down', that was put together by Sedgley. The replacement barrel was made from a (1905 dated) 1903 Springfield barrel. The tight chamber would accept factory ammo and my F.L. resized cases. It would not accept a 'fired case' from any of my other Krags).

Re: Chamber differences and tough to close bolt

BR,

Can you clarify which is the old and which is the new chamber. It looks like the top one is showing a recess for the rim. All the 1898s (total of 3) that I have seen are later than the 213000. They do not have the rim recess. Did early have the recess? If so the late bolts will not fit in the early receivers?

To add confusion the SAAMI drawings all show the recess. So you have to subtract the rim thickness to compare them. Not sure if you subtract the Maximum thickness or an average thickness. Neither seems to work out. If I am understanding your drawing the dimension changed by .030, which is huge.

Can you clarify which is the old and which is the new chamber. It looks like the top one is showing a recess for the rim. All the 1898s (total of 3) that I have seen are later than the 213000. They do not have the rim recess. Did early have the recess? If so the late bolts will not fit in the early receivers?

To add confusion the SAAMI drawings all show the recess. So you have to subtract the rim thickness to compare them. Not sure if you subtract the Maximum thickness or an average thickness. Neither seems to work out. If I am understanding your drawing the dimension changed by .030, which is huge.

- butlersrangers

- Posts: 9898

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Chamber differences and tough to close bolt

FredC: I have separated the drawings to make it clearer: Old vs. New.

The Krag chamber was never recessed for the rim. The old drawing could give that impression, so I have eliminated the confusing shade areas.

Good eye on the .030" dimensional difference! Old Ordnance Dept. Mistake?

I suspect, the difference may actually be .003".

The Krag chamber was never recessed for the rim. The old drawing could give that impression, so I have eliminated the confusing shade areas.

Good eye on the .030" dimensional difference! Old Ordnance Dept. Mistake?

I suspect, the difference may actually be .003".

Re: Chamber differences and tough to close bolt

Any chance the drawing is for proposed changes that never made it into production? The radius on the outside is not on my barrels. I made a detailed drawing with lengths and diameters that was sent to Pacnor for making my barrel. The taper ended where the parallel 1 inch diameter started.

Looking at the SAAMI drawing of both the cartridge and chamber they have a .155 radius at the corner we have been discussing. I did not measure it on the 30/40 Remington cases on hand but it is there. That radius makes it much more difficult to see where that now theoretical line is (1.65/1.62). Again on the SAAMI drawing neither worked out on the math.

All said and done the SAAMI specs do not have to match the original SA drawings or actual dimension of the finished product. Just safe in practice with most firearms manufactured. If the .030 difference is real could explain part of CoRofleMan's difficulty. Just hope his rifle was not reamed for 30-06 blanks.

Looking at the SAAMI drawing of both the cartridge and chamber they have a .155 radius at the corner we have been discussing. I did not measure it on the 30/40 Remington cases on hand but it is there. That radius makes it much more difficult to see where that now theoretical line is (1.65/1.62). Again on the SAAMI drawing neither worked out on the math.

All said and done the SAAMI specs do not have to match the original SA drawings or actual dimension of the finished product. Just safe in practice with most firearms manufactured. If the .030 difference is real could explain part of CoRofleMan's difficulty. Just hope his rifle was not reamed for 30-06 blanks.

- butlersrangers

- Posts: 9898

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Chamber differences and tough to close bolt

I am not sure where Frank Mallory got the Ordnance drawings. It would take some digging in original reports to find them.

-

CoRifleman

- Posts: 36

- Joined: Sun Jan 19, 2020 3:28 pm

Re: Chamber differences and tough to close bolt

Thank you all for the input. I'll keep it ALL in mind when I finally get the rifle back out to shoot.

In the meantime, I ordered a single stage cast iron Lee press today (my regular press is the classic turret which is a cast iron base but the turret is milled aluminum and the turret ring is cast aluminum. I'm going to see if the cast iron single stage doesn't do a better job on hard to press shoulders and full length cases.

Thanks again.

In the meantime, I ordered a single stage cast iron Lee press today (my regular press is the classic turret which is a cast iron base but the turret is milled aluminum and the turret ring is cast aluminum. I'm going to see if the cast iron single stage doesn't do a better job on hard to press shoulders and full length cases.

Thanks again.

- butlersrangers

- Posts: 9898

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Chamber differences and tough to close bolt

'CoRifleman':

On your next outing, I would suggest keeping the 'fired' brass segregated by rifle.

Try reloading the cases with just 'neck-sizing' and see how that works out for you.

There is a lot of virtue in having 'fire-formed' cases.

A dap of red nail-polish on the base of cases fired in one of your rifles can simplify identification.

On your next outing, I would suggest keeping the 'fired' brass segregated by rifle.

Try reloading the cases with just 'neck-sizing' and see how that works out for you.

There is a lot of virtue in having 'fire-formed' cases.

A dap of red nail-polish on the base of cases fired in one of your rifles can simplify identification.

Re: Chamber differences and tough to close bolt

Right now we are thinking that peculiar circumstances led to the extreme effort to resize and annealing the shoulder to solve the problem. The new press and segregating your brass may make it a non problem.

Now we have a theoretical quandary on did the shoulder length change with #213000. I did notice the SAAMI chamber dimension notes the chamber shoulder has a .155 MAX radius. I guess .002 is less than max and would be much easier to measure. I sold my 35/40 reamer to a new KCA member so I can not verify it but I remember a miniscule or nonexistent radius on that corner. May have been a SA practice to make the corner with a minimal radius when new and hone a radius on the corners as it got dull. When .155 R was reached the reamer was discarded.

Just measured the shoulder depth on a loose Krag barrel and got 1.669 calculating the shoulder depth from SAAMI using a .064 rim thickness I got 1.6644 with a plus or minus tolerance of .015. Kind of odd to have a plus or minus tolerance of .015 from a four place decimal dimension, but 1.669 measured is in tolerance. Way different than the 1.62 on the Frank Mallory sourced drawing. The mystery is getting deeper.

The loose barrel just measured was from #410864 so it was later production, #266389 is similar but it is assembled and the measurement is not exact.

Now we have a theoretical quandary on did the shoulder length change with #213000. I did notice the SAAMI chamber dimension notes the chamber shoulder has a .155 MAX radius. I guess .002 is less than max and would be much easier to measure. I sold my 35/40 reamer to a new KCA member so I can not verify it but I remember a miniscule or nonexistent radius on that corner. May have been a SA practice to make the corner with a minimal radius when new and hone a radius on the corners as it got dull. When .155 R was reached the reamer was discarded.

Just measured the shoulder depth on a loose Krag barrel and got 1.669 calculating the shoulder depth from SAAMI using a .064 rim thickness I got 1.6644 with a plus or minus tolerance of .015. Kind of odd to have a plus or minus tolerance of .015 from a four place decimal dimension, but 1.669 measured is in tolerance. Way different than the 1.62 on the Frank Mallory sourced drawing. The mystery is getting deeper.

The loose barrel just measured was from #410864 so it was later production, #266389 is similar but it is assembled and the measurement is not exact.

- butlersrangers

- Posts: 9898

- Joined: Wed Oct 07, 2009 11:35 pm

- Location: Below the Bridge, Michigan

Re: Chamber differences and tough to close bolt

I've got nothing more.

Most references, in regard to barrels, cite early change of muzzle crown from 'flat' crown to a crown with radius, (during model 1892 production), and, (during model 1898 production), a change of barrel breech-face from square-cornered to beveled-cornered.

Frank Mallory, "Krag Rifle Story", reports the change in chamber dimensions during 1899. (I am sure Mallory found a factual basis for this).

Precision chamber casts of a model 1896 barrel and a late model 1898 barrel would be interesting to compare.

I am sure measuring the dimensions of brass, fired in two such chambers, would have the additional variable of differences in free-travel (head-space) of the respective actions.

Note - In the drawings used by Mallory, measurements were taken from the front of the cartridge rim. Rim thickness is absent.

Drawings based on SAAMI dimensions include the cartridge rim thickness, of .064".

Most references, in regard to barrels, cite early change of muzzle crown from 'flat' crown to a crown with radius, (during model 1892 production), and, (during model 1898 production), a change of barrel breech-face from square-cornered to beveled-cornered.

Frank Mallory, "Krag Rifle Story", reports the change in chamber dimensions during 1899. (I am sure Mallory found a factual basis for this).

Precision chamber casts of a model 1896 barrel and a late model 1898 barrel would be interesting to compare.

I am sure measuring the dimensions of brass, fired in two such chambers, would have the additional variable of differences in free-travel (head-space) of the respective actions.

Note - In the drawings used by Mallory, measurements were taken from the front of the cartridge rim. Rim thickness is absent.

Drawings based on SAAMI dimensions include the cartridge rim thickness, of .064".