I have to do some cold bluing repairs on a piece (rest assured it's not a Krag!!) I have some old stuff I'm tossing. What is the latest and best version of cold blue these days? Brownells, Birchwood, Shooters Solution,....???

Anyone use anything lately? I've read a bunch of things online and there are a few favorites. How about you folks?

Cold Blue products

Re: Cold Blue products

I have to do some cold bluing repairs on a piece (rest assured it's not a Krag!!) I have some old stuff I'm tossing. What is the latest and best version of cold blue these days? Brownells, Birchwood, Shooters Solution,....???

Anyone use anything lately? I've read a bunch of things online and there are a few favorites. How about you folks?

Have you ever heard of "rust bluing"?

It is used on high end custom guns & English doubles that have soft soldered barrells.

What it amounts to is getting an even coating of rust, then boiling or steaming the part to turn the brown ferros oxide black. then, the surface is carded off. My results turned the oxide a dark chocolate brown, but underneath it was black when I carded off the surface. The 1st cycle will result in a gray color. You repeat the process until you get the desired darkness of color.

It is labor entensive, but not difficult. Small parts can be done on the kitchen stove in a pot. For a barreled action you need a long trough or a vertical tube if you use steam.

Google "rust bluing" & you will find lots of information. The result is more durable than "hot blue".

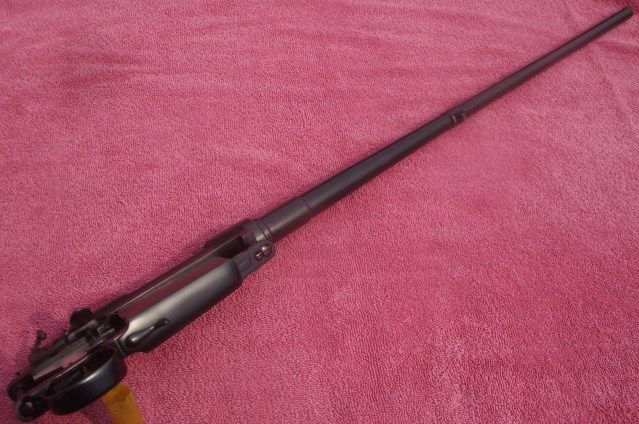

Here is a Mauser custom I put together & rust blued.The barreled action took 9 cycles to get the desired color. The smaller parts took fewer cycles.

-

Bill Rogers

- Posts: 42

- Joined: Fri Oct 03, 2014 10:17 am

Re: Cold Blue products

Thanks It's for a SA .22 revolver with really no marks except for a small thin line/mark where the cylinder rolls. it's only on the 2 cylinders. As far as soaking if i go your route i won't need a very big pot or trough. Thanks again.

Re: Cold Blue products

Thanks It's for a SA .22 revolver with really no marks except for a small thin line/mark where the cylinder rolls. it's only on the 2 cylinders. As far as soaking if i go your route i won't need a very big pot or trough. Thanks again.

I've used Birchwood Casey Permablue patse for small touch up. Clean the part in acetone & just apply to the damaged area W/a Q-tip.

You probably won't be able to match the factory bluing if you just do 1 part. a revolver could be done on the stove top in a kettle large enough to handle the frame/barrel.

I could probably be done in a weekend if you had the time to spend about 1/2 hour to do the carding/application once every 4 hours or so depending on the humidity.

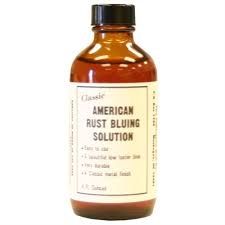

If you decide to do the whole gun here is the product I used. Brownells carries it.

This is what the part should look lke before boiling.

After boiling it will look something like this.

I used an air die grinder W/a wire brush head to card the surface.

You needn't be too particular about the water. I used well water that went through a softener. I'm not sure if chlorinated tap water would cause problems or not.

I am also interestd in a better "cold blue" as I have a peep sight that needs some touch-up & I can't completely dis-assemble it to rust blue it.

-

Bill Rogers

- Posts: 42

- Joined: Fri Oct 03, 2014 10:17 am

Re: Cold Blue products

Thanks i like the look of it. I'll make it a winter project on a cold day when i don't want to go anywhere.

Re: Cold Blue products

Thanks i like the look of it. I'll make it a winter project on a cold day when i don't want to go anywhere.

Winter is the best time to finish stocks, summer is the best time to rust blue.

It all has to do with humidity & rusting.

That being said, you can still get good rust blue results in winter, it just takes a bit longer to get a good coating of rust due to low humudity inside a heated house.

If you have a basement, that would be the place to hang your parts when rusting them.

Use acetone to de-grease before each application & then wear gloves or avoid touching the surfaces being rusted after de-greasing. I drive a slighly over sized wooden dowel into the muzzle to use as a handle. Take it out after the boil & run a patch through the bore while it is still hot.

After you card off the surface, insert the dowel/handle again for the next degrease, application, rust, boil cycle.

It's a lot of work, but after each cycle you will get a darker color. Keep cycling the parts until you get the color you want. You will be rewarded with a rich, dark charcoal gray satin finish that is extremely durable & rear resistant.

This is the finish that is prefered on high end custom guns. It is also the only durable blue finish that I know of that can be used if there are soft soldered parts on the gun. The Mauser pictured above had the barrel band swivel stud & cartridge stops in the magazine applied with soft solder.

Re: Cold Blue products

Dads Krag: New to the forum and have been reading through the older posts.

I have had great results with Van's cold blue. It is an excellent product. Google vans cold blue. It has great reviews as well.

I have had great results with Van's cold blue. It is an excellent product. Google vans cold blue. It has great reviews as well.