The best guess, I could offer, was that maybe they identified steel lot, production period, or a bolt passing inspection steps or proof testing.

(1903 Springfield authority, John Beard, on another forum, has provided his research in the form of "Steel Lot Code Charts". These just pertain to 1903 Bolts, and help identify year ranges and manufacturer. Some of the earlier codes are simple & odd letter and number combinations. Possibly, this could be the purpose of the markings we see on our Krag Bolts)?

Some KCA members speculated that the markings might relate to certain bolt dimensions to assist proper head-space and function.

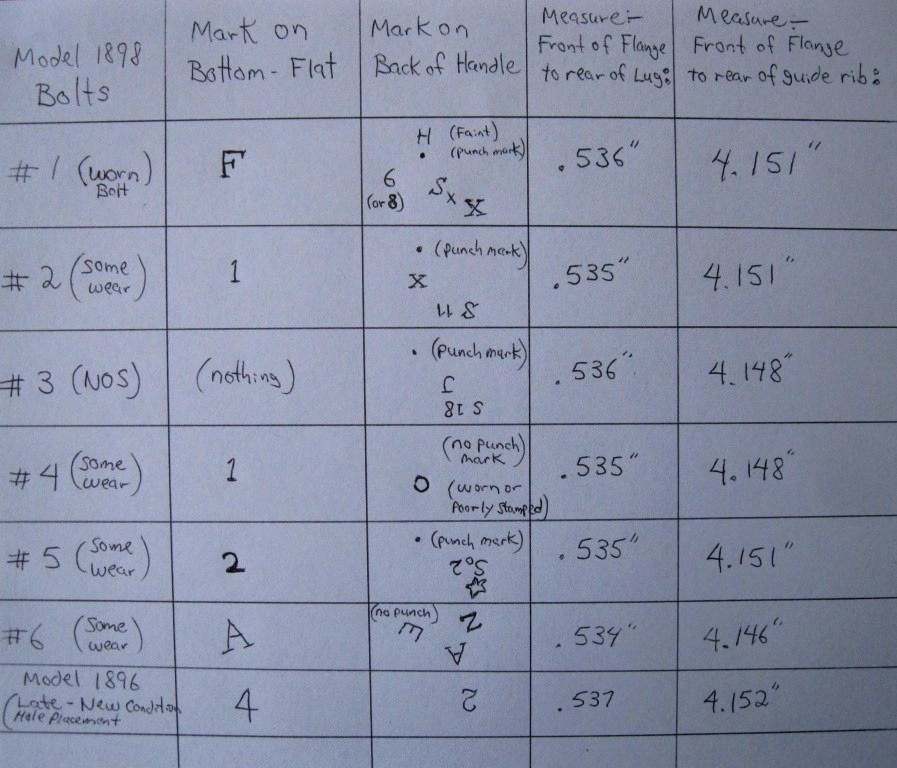

FWIW - I examined six model 1898 bolts and one model 1896 bolt, today.

I noted their markings. Some of the bolts, but not all, had a 'Rockwell like' punch mark, on the back of the bolt-handle. None of the bolts had identical markings.

(I could detect no regular pattern to the marking system).

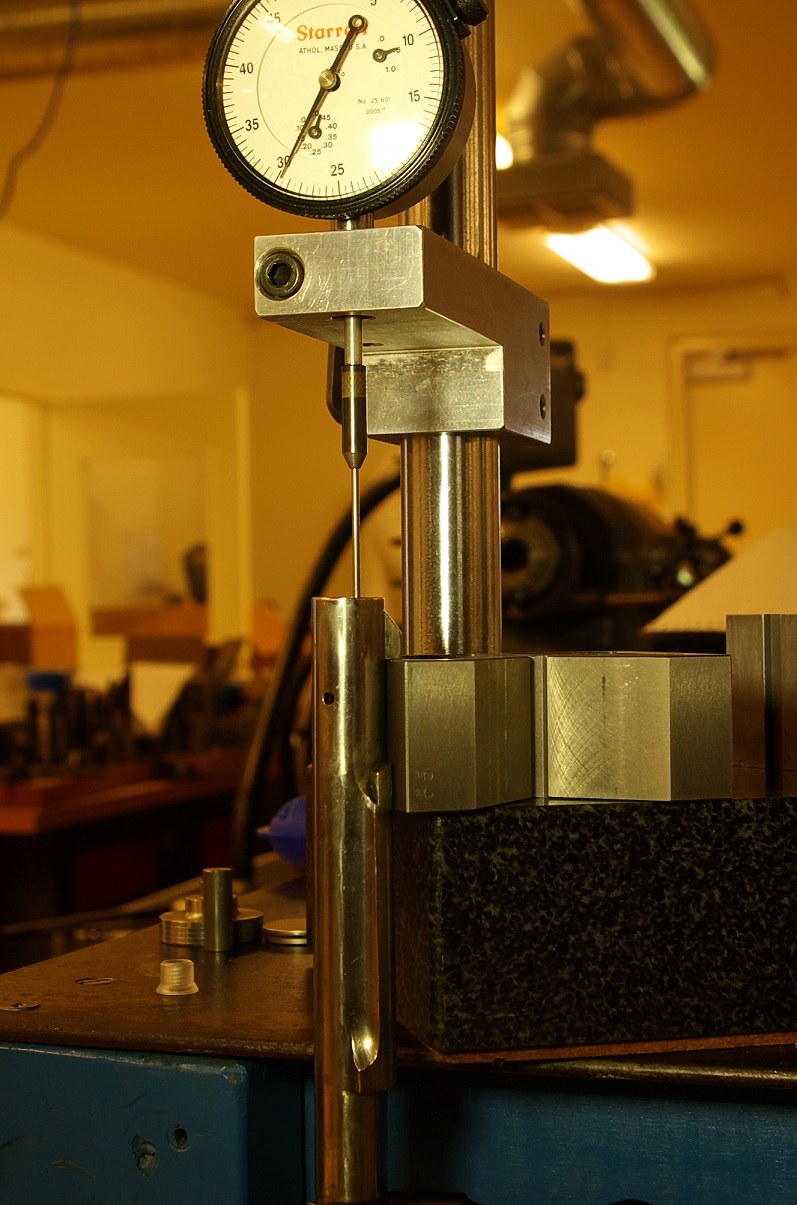

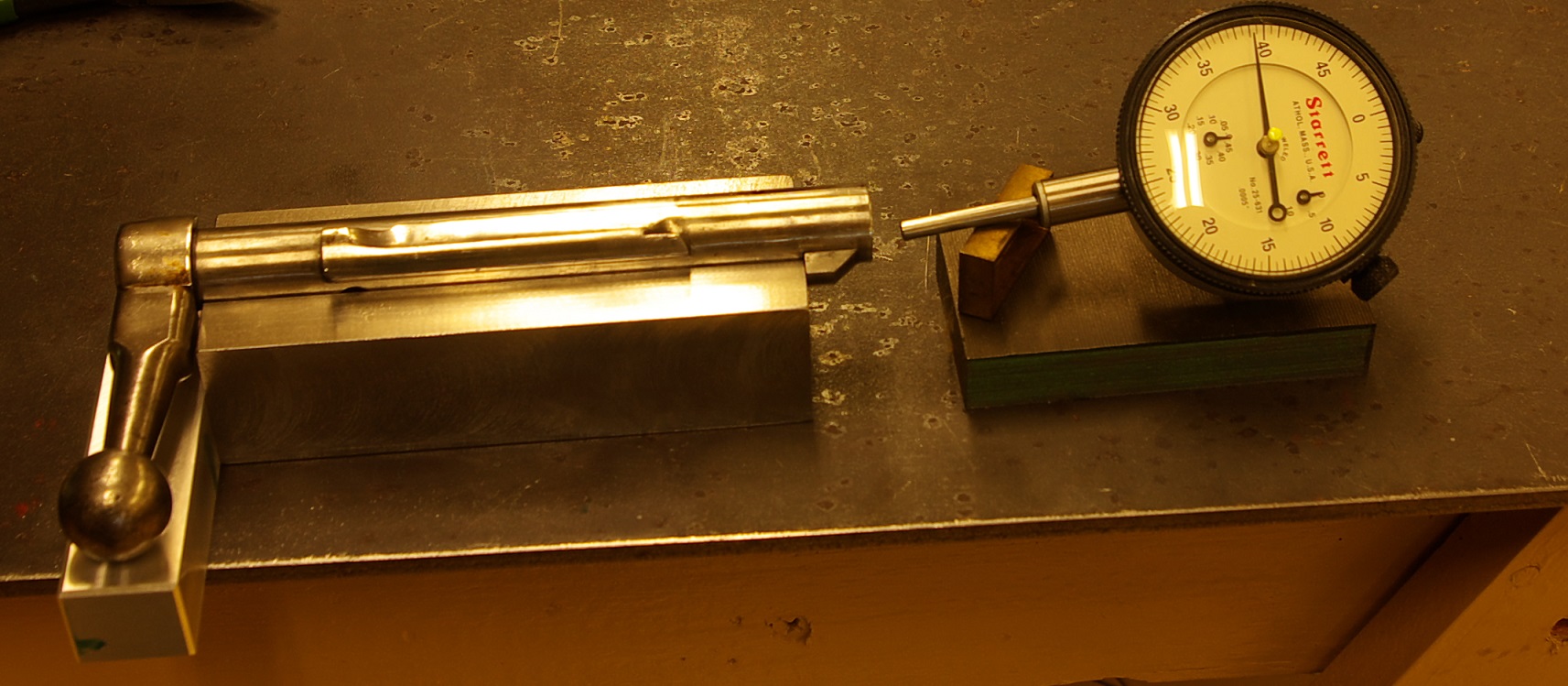

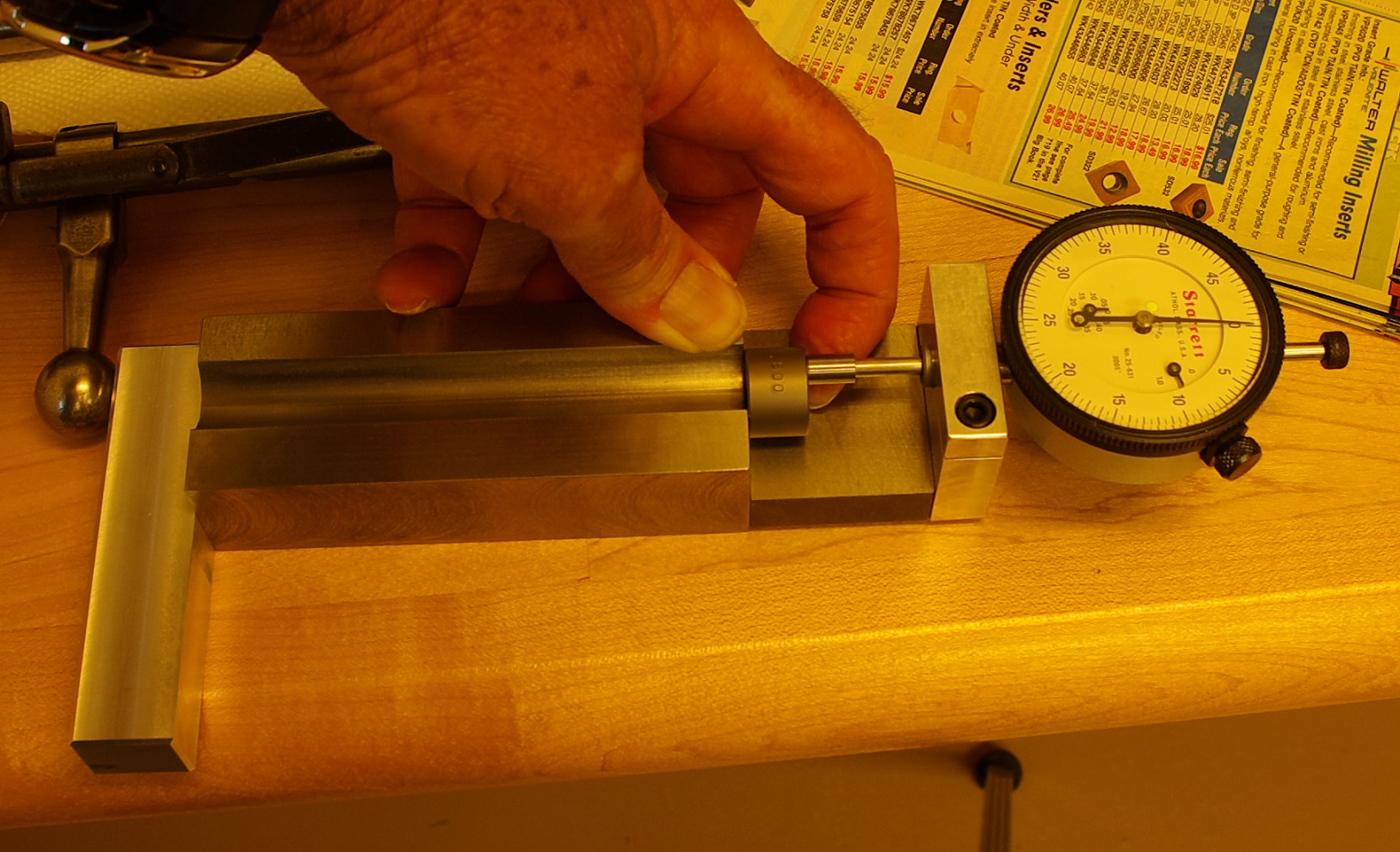

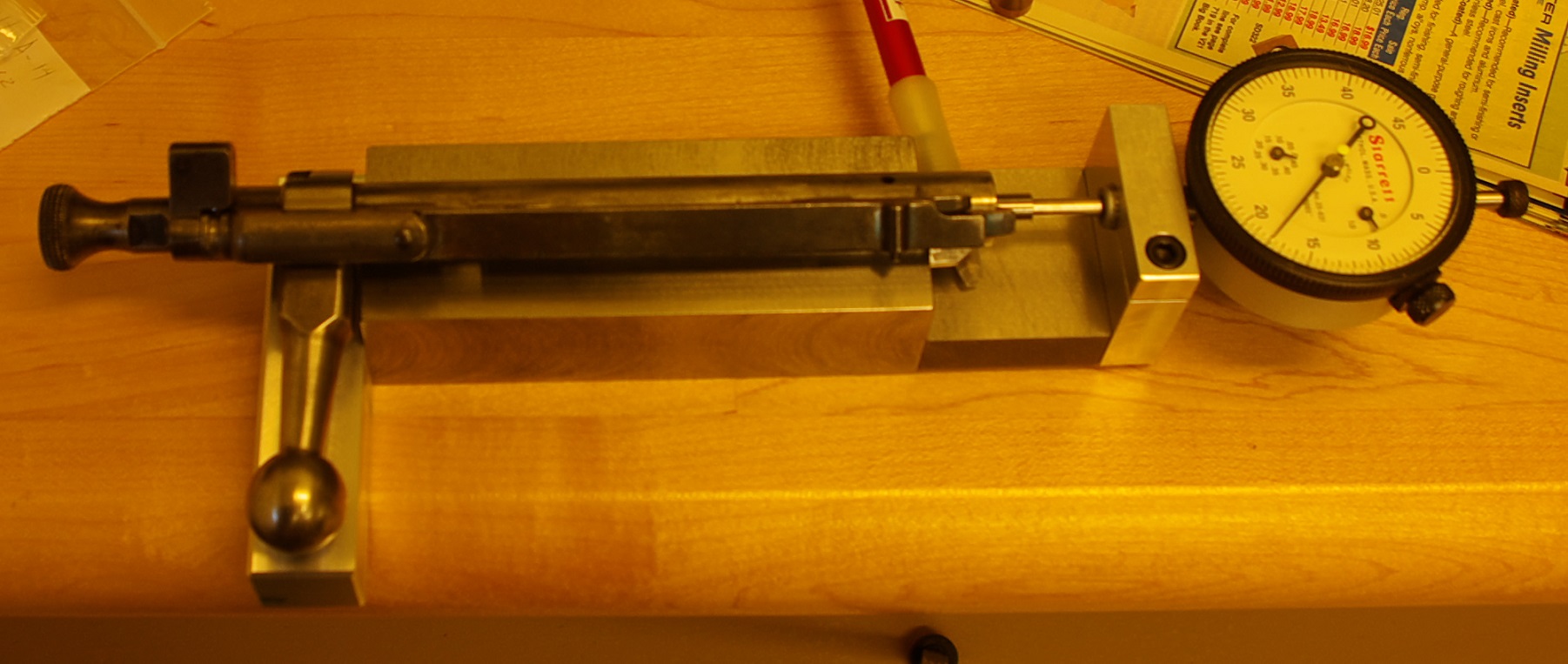

I measured with a vernier-caliper: 1. The distance from the front of the bolt-flange to the rear of the locking-lug. & 2. The distance from the front of the bolt-flange to the rear of the guide-rib.

(These seemed easy and relevant comparison points to me).

Frankly, I was surprised by the closeness of dimensions from bolt to bolt.

Here is a tabulation of my observations.