Page 1 of 1

Trigger Job

Posted: Tue Mar 31, 2020 10:23 pm

by Cannoncocker

Can anybody out there give me some guidance on a trigger job for my krag? It's my preferred M rifle in GSM matches just needs a cleaner trigger. Maybe around 3.75lbs. Thanks!

Re: Trigger Job

Posted: Wed Apr 01, 2020 2:00 pm

by FredC

I take it in your competition you can not use a commercial replacement trigger. Too bad there is one out there that someone needs to test and give us a report on its performance.

Here is a thread where modifications and that commercial trigger has been discussed:http://www.kragcollectorsassociation.org/cgi-bin/yabb2/YaBB.pl?num=1576078910/0#0

Here is a thread to make sure any modifications are sober and sane:

http://www.kragcollectorsassociation.org/cgi-bin/yabb2/YaBB.pl?num=1578930892/0

The Krag trigger from Springfield Armory is intrinsically safe. Too many or the wrong modification could make it dangerous. My case it was the wrong spring and a ding in the hole the spring is inserted. It worked fine for hundreds of pulls then it did not for a couple then worked fine again making for a hair pulling effort to figure out why.

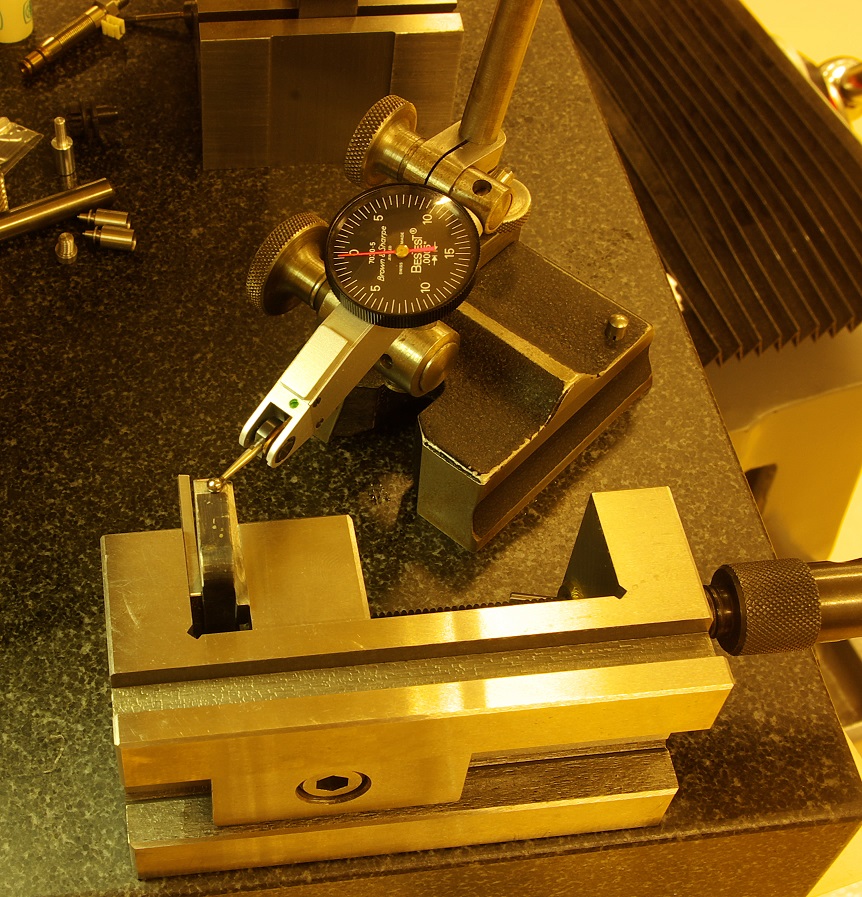

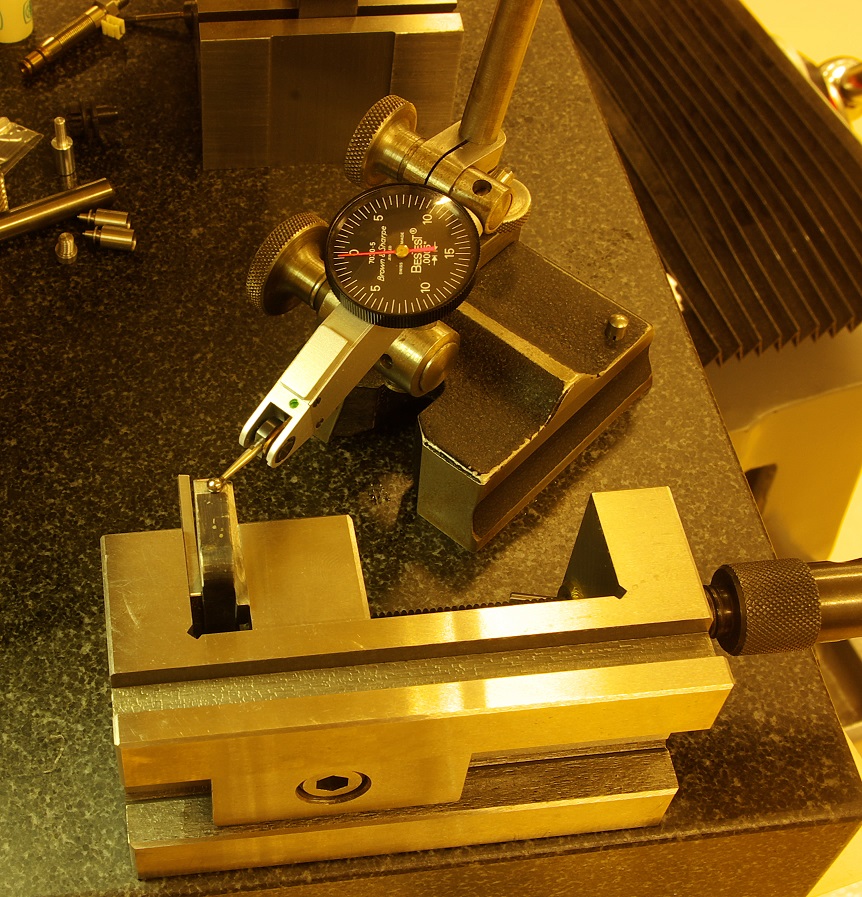

A couple more photos that were not in either thread here, 1st will be how I squared up the trigger sear after it was incorrectly honed. I indicated the remaining flat portion till it was flat then surface ground it till it cleaned up. Total material removed .0021 inches. Important to take very little as the sear is case hardened and you do not want to go through the case. surface grinder left a finish better that original but not quite as smooth as honed. Broke the sharp edge with a fine hone leaving a .001 to .002 radius instead of a sharp corner.

I think there is a link in one of these threads to an additional thread on reassembling the trigger/sear assembly. If not I will add it later with other photos.

There is room for shortening the original spring, but you must not over do it. The trigger must return to fully engaged when you pull it to the brink of discharge then let off. Only way to do that is trial and error. Get several new springs from Grandpa's and shorten one gradually till it no longer returns. Then do another plus at least 10% so it will always return.

Make sure the 1st stage and second stage cam surfaces are smooth and lub

Re: Trigger Job

Posted: Wed Apr 01, 2020 5:05 pm

by FredC

Ran out of characters on the proceeding post, if you add an "e." the last word will make more sense.

Also the 2 links were the same now corrected if anyone has tried to follow them.

Sorry for if anyone tried to follow them before.

Re: Trigger Job

Posted: Thu Apr 02, 2020 2:50 pm

by Whig

Whew! Thanks for that correction, Fred!

I've been trying to "LUB" my cam surfaces for a while now and was getting nowhere.

Now, I've lubed them and they work fine.

Timing is everything!

Re: Trigger Job

Posted: Thu Apr 02, 2020 3:08 pm

by FredC

Whew! Thanks for that correction, Fred!

I've been trying to "LUB" my cam surfaces for a while now and was getting nowhere.

Now, I've lubed them and they work fine.

Timing is everything!

Too funny!

On the first link Paul in post #13 says with proper honing and lube he got 3.0 lbs pull. So the 3.5 goal is certainly doable and legal.

Re: Trigger Job

Posted: Sat Apr 04, 2020 1:40 pm

by Cannoncocker

Thanks for the info. Very helpful!