Page 3 of 3

Re: New member…Krag 6.5x55

Posted: Mon Jun 12, 2023 6:03 pm

by butlersrangers

A real shot in the dark and unlikely, because the OP is only experiencing the bolt resistance when firing 'live' rounds, but these points can be sources of 'drag' on the bolt's rearward movement.

I don't currently have a Norwegian Krag, so a U.S. model was used.

An extractor that rubs against the receiver can add a lot of stickiness to bolt travel.

Re: New member…Krag 6.5x55

Posted: Mon Jun 12, 2023 7:03 pm

by Parashooter

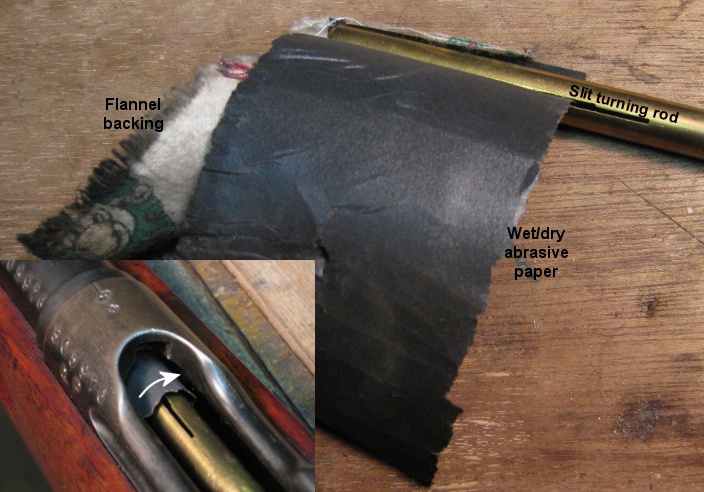

Try polishing the chamber with a setup as pictured below. Turn the slit rod with a hand-held power drill, using plenty of light oil on the abrasive. Don't over-do; doesn't normally take much. Nothing coarser than 400 grit to start - then finish with something finer. Clean chamber and bore thoroughly when done, then test-fire.

IMR 4831 is a poor choice for such a reduced load. Peak pressure is only some 21000 psi and about 15% of powder is unburnt (QuickLoad estimates). This could be leaving enough unburnt granules in the chamber to gum things up. An appropriate charge of faster powder might be helpful.

- ChamberPolish.jpg (140.74 KiB) Viewed 17298 times

Re: New member…Krag 6.5x55

Posted: Wed Jun 14, 2023 5:53 pm

by Sunshineboys

Thanks parashooter. I took your advise. I bought a 3/8” hardwood dowel and cut a slit in the end. I used 320 grit first and followed with 600 after that. Just before starting this process I did notice a rough spot near the mouth of the chamber…discoloured and rough. I used a metal skewer I had here and could feel roughness. So now I will head to camp and fire a round to see. Waiting for a break in the rain.

Re: New member…Krag 6.5x55

Posted: Wed Jun 14, 2023 8:36 pm

by Parashooter

My advice was a metal turning rod and no abrasive coarser than 400-grit, so good luck with your setup - hoping you don't jam and break the wooden dowel and/or ovalize the chamber with the 320-grit. Proceed with care and you might be OK.

Re: New member…Krag 6.5x55

Posted: Thu Jun 15, 2023 9:14 am

by Sunshineboys

The hardwood dowel worked perfectly. I could not buy 400 grit at my local store so tried 320. 600 used for final spin. I am trying it today. I found it took a bit more than I expected to remove the spot. Not wanting to do too much in the chamber. Will report back. Dave

Re: New member…Krag 6.5x55

Posted: Thu Jun 15, 2023 2:07 pm

by butlersrangers

Dave - Was the 'rough spot' at the front (throat) of the chamber or at the rear (breech-end) of your chamber?

A final polish might be done with a bronze bore-brush wrapped with #0000 steel wool, held in a section of aluminum cleaning-rod, and soaked with solvent or penetrating oil. The rod section can be spun with a variable-speed electric drill.

I hope the chamber polish solves the stubborn extraction.

Re: New member…Krag 6.5x55

Posted: Thu Jun 15, 2023 4:28 pm

by Sunshineboys

The rough spot was at the rear of the chamber. I am ecstatic to advise that I fired it just now and it ejected easily Thanks to everyone here for your sage advise. I did not expect such immediate response. To all….thanks. Dave

Re: New member…Krag 6.5x55

Posted: Wed Aug 23, 2023 8:48 am

by Sunshineboys

Hopefully a FINAL report! In spite of my last posts regarding the sticking cases which are difficult to extract I still had problems. A friend sent me some 1000 and 2000 grit emery cloth. I polished the chamber again with these and the problem is gone. Now able to move on to try some cast bullets. Thanks to those who helped. Dave